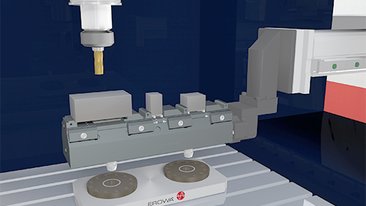

EDM TOOLING SYSTEM

The tooling system for EDM and milling

Fast and precise resetting in tool-making and in light chip removal: save time and money by using the EROWA EDM Tooling System.

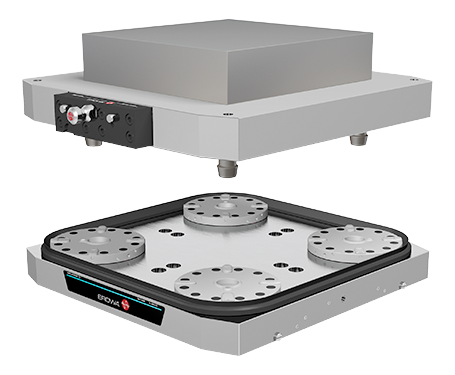

The basis of this workpiece clamping system is constituted by the EROWA ITS chucks, which can be fitted and aligned on the machine table or on the machine quill.

Workpiece and electrodes are fitted to and set up on system carriers such as pallets, electrode holders, centering plates, etc. – and production can start.

A suitable variant for every job

The applications of ITS chucks are as many-faceted as the challenges presented by jobs in precision mechanics and tool- and mold-making.

The applications of ITS chucks are as many-faceted as the challenges presented by jobs in precision mechanics and tool- and mold-making.

Depending on workpiece size, we offer a considerable range of different suitable chuck variants.

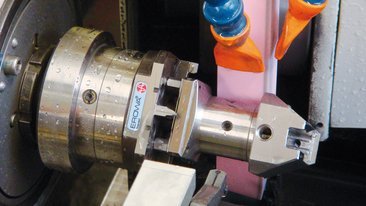

Quick resetting

Fixed reference positions: the chucking spigot and the centering plate guarantee precise positioning in the chuck and powerful clamping of electrode holders.

Fixed reference positions: the chucking spigot and the centering plate guarantee precise positioning in the chuck and powerful clamping of electrode holders.

The next job is prepared while the machine is productive. Then, there is a quick resetting operation, without loss of time through re-alignment and re-positioning of the electrode holder.

Universal interface

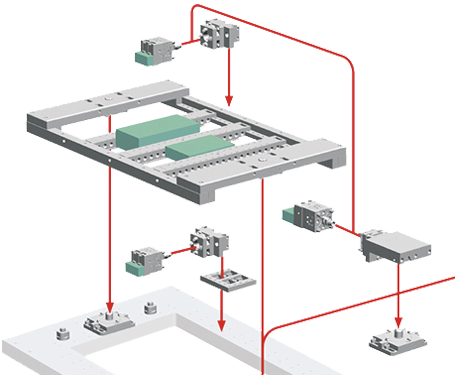

EROWA ITS chucks can be used universally on all machines.

EROWA ITS chucks can be used universally on all machines.

Workpieces and electrodes pass through the entire production chain (turning, milling, grinding, EDM, WEDM, and measuring and presetting stations) palletized on the same system carrier.

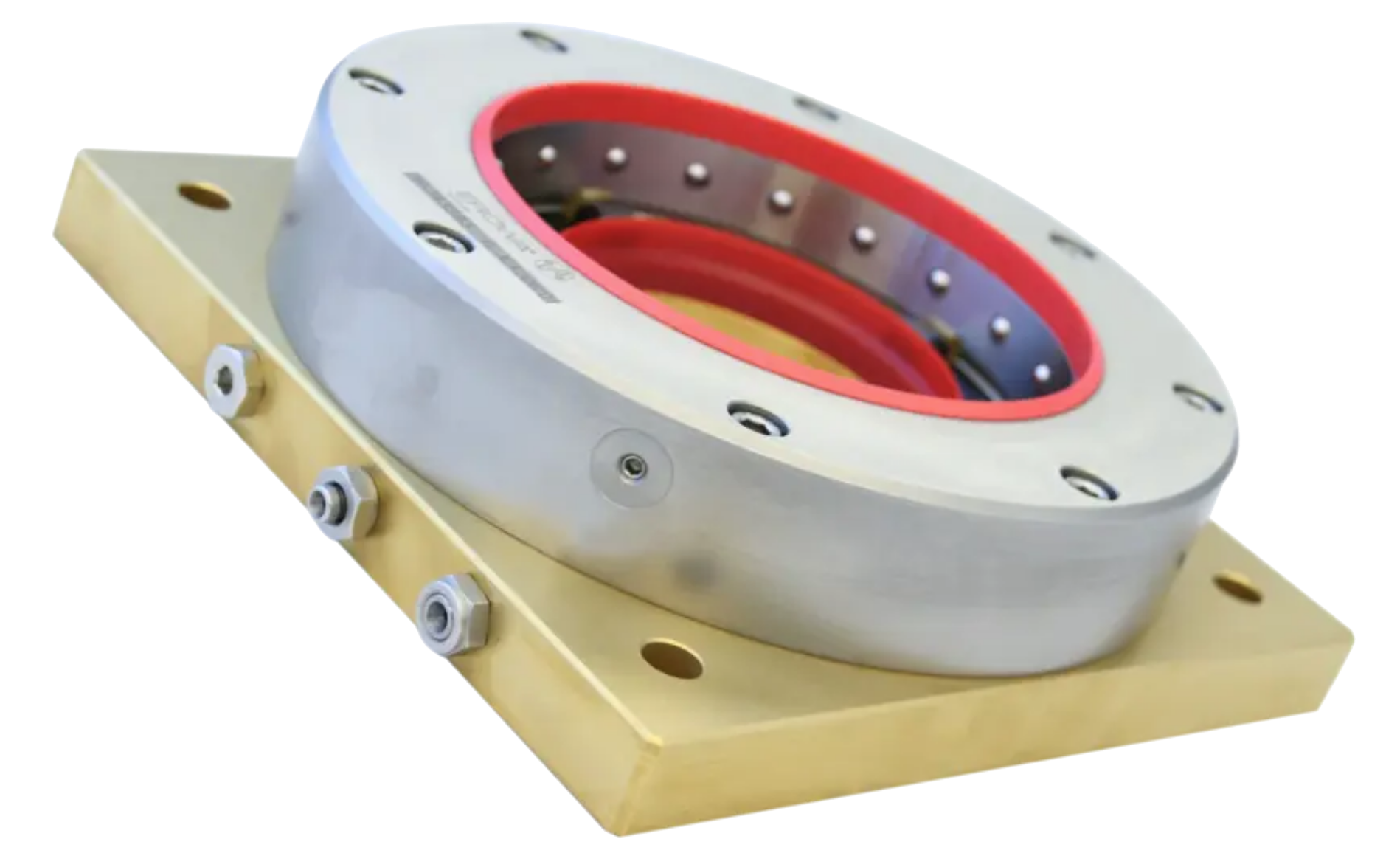

Precise

Precision and reliability in the machine tank and on the quill of the EDM machine.

Precision and reliability in the machine tank and on the quill of the EDM machine.

Workpiece holders are divisible 4 x 90°.

The repeatability of 0.002mm guarantees universal and precise positioning.

Safe and sealed

The sealing plate of the EROWA ITS 50 Holder C and the sealing ring provide a form-fit seal.

The sealing plate of the EROWA ITS 50 Holder C and the sealing ring provide a form-fit seal.

This ensures that the chuck is optimally protected against contamination and the penetration of liquids.

Can be automated directly

The CleverClamp base rail can be automated directly. The robot places the workpiece carrier on the machine with precision and speed.

The CleverClamp base rail can be automated directly. The robot places the workpiece carrier on the machine with precision and speed.

The EWIS™ identification system provides you with a safe overviw of magazine positions and pallets.

Workholding

Systems

A standardized interface between machine and workpiece or clamping tool enable fast and precise setup.

Measuring

Systems

Eliminate set up times on machines, making them more productive and relieving them of operations that are not their responsibility.

Automation Solutions

Thanks to the Erowa flexible automation system, machine tools can significantly increase daily production hours.

Integration Software

The integration of machine tools and company systems (IOT) through a synoptic management software speeds up the dialogue between department.