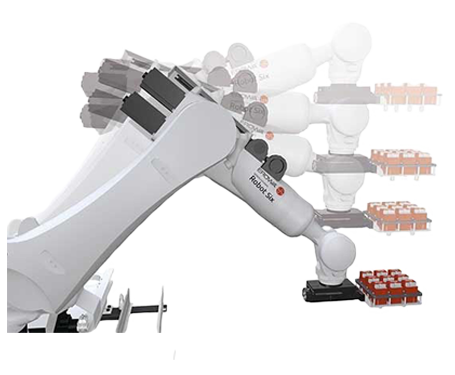

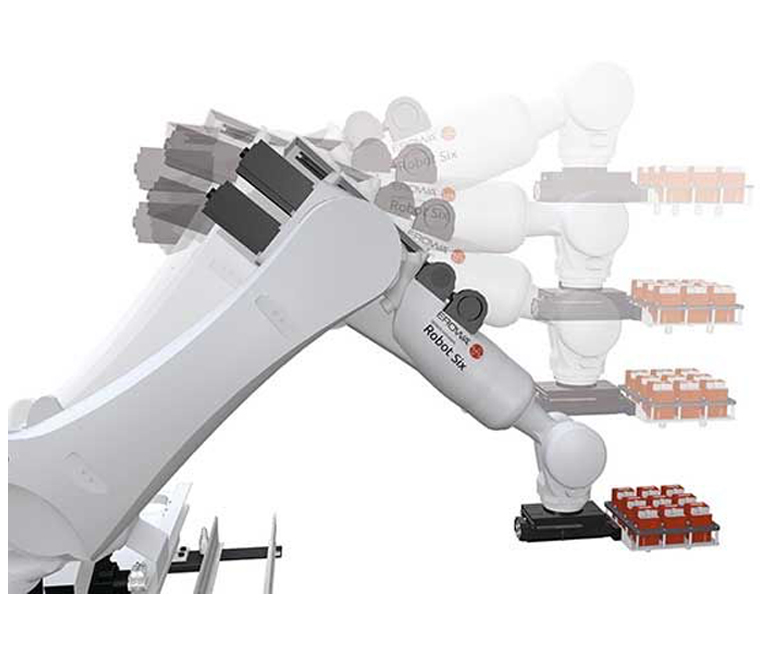

ROBOT SIX

The best of both worlds

The Robot Six combines the versatility of the six-axis robot with the flexibility of the FMC Erowa concept.

On the one hand the productivity, speed and total movement guaranteed by the six axes of the robot, on the other hand the flexibility, the automatic setup, the robotized series change guaranteed by the modularity of the Erowa system.

Together to obtain hybrid production systems, with batches of raw or semi-finished parts loaded into the machine on palletized equipment.

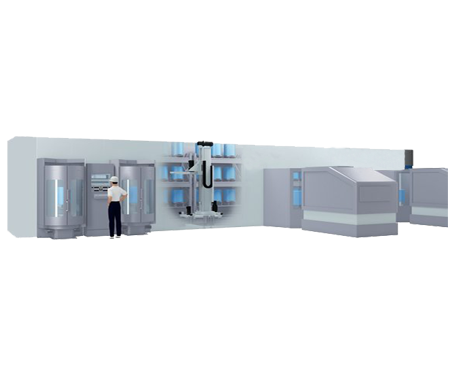

Max Specs

For projects that include weights of up to 1000 kg and rail length up to 30 meters.

For projects that include weights of up to 1000 kg and rail length up to 30 meters.

How many pallet slots?

The requested autonomy and the average processing time per workpiece will determine the necessary number of pallet slots.

The requested autonomy and the average processing time per workpiece will determine the necessary number of pallet slots.

Always there when needed

To prevent any idle time it is important to have the Robot move quicker than the process time in the machine.

To prevent any idle time it is important to have the Robot move quicker than the process time in the machine.

Efficiency

Overall Equipment Effectiveness, short OEE, states how good the cell works and if anything what you may improve.

Overall Equipment Effectiveness, short OEE, states how good the cell works and if anything what you may improve.

2D scanner for access safety

A 2D scanner continuously monitors the operator area.

If a person is detected, pallet changes are not allowed. If the area is free, the Robot loads the machine as planned.

Workholding

Systems

A standardized interface between machine and workpiece or clamping tool enable fast and precise setup.

Measuring

Systems

Eliminate set up times on machines, making them more productive and relieving them of operations that are not their responsibility.

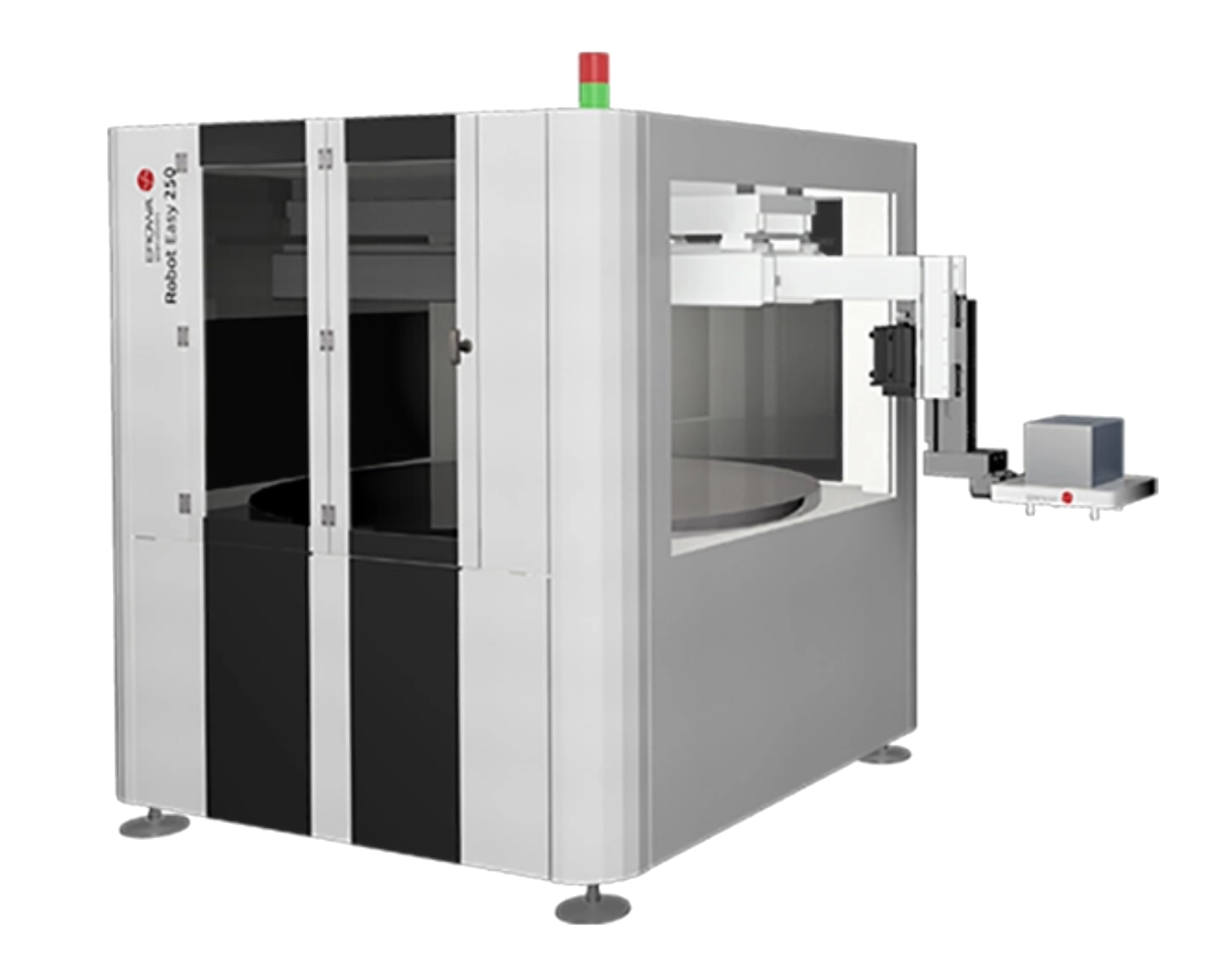

Automation Solutions

Thanks to the Erowa flexible automation system, machine tools can significantly increase daily production hours.

Integration Software

The integration of machine tools and company systems (IOT) through a synoptic management software speeds up the dialogue between department.