LOADMASTER

Automation for metalworking machines

Mechanical engineering quality at the highest standard, over 30 years of experience in factory automation, globally represented. It can really be said that the handling devices of the LoadMaster series are loading masterfully. And this at remarkably pleasant investment and return on investment factors.

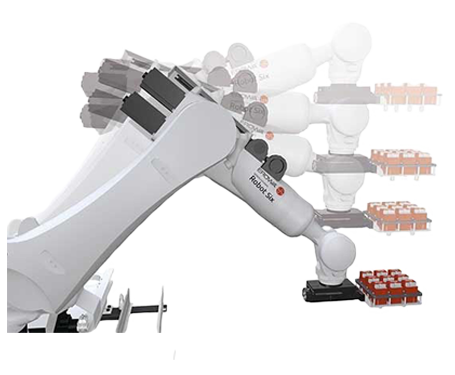

Superior loading

Up to 4’000 kg transfer weight. Thanks to the ingenious kinematics with very little space requirement. With the 360° swivel function, any position in the magazine and on the machine table may be reliably reached.

Up to 4’000 kg transfer weight. Thanks to the ingenious kinematics with very little space requirement. With the 360° swivel function, any position in the magazine and on the machine table may be reliably reached.

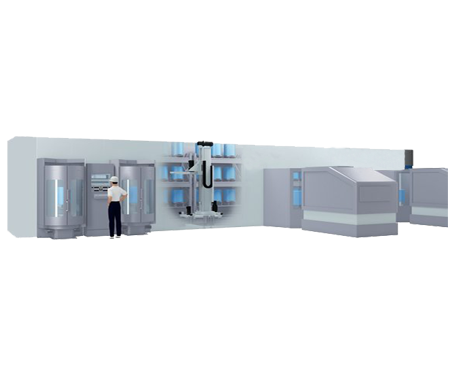

Superior loading

The magazines are rising high. The storage locations are arranged on two, three or four levels in a very cost-effective and space-saving manner. The individual levels are optimally configured for the usual workpiece sizes.

The magazines are rising high. The storage locations are arranged on two, three or four levels in a very cost-effective and space-saving manner. The individual levels are optimally configured for the usual workpiece sizes.

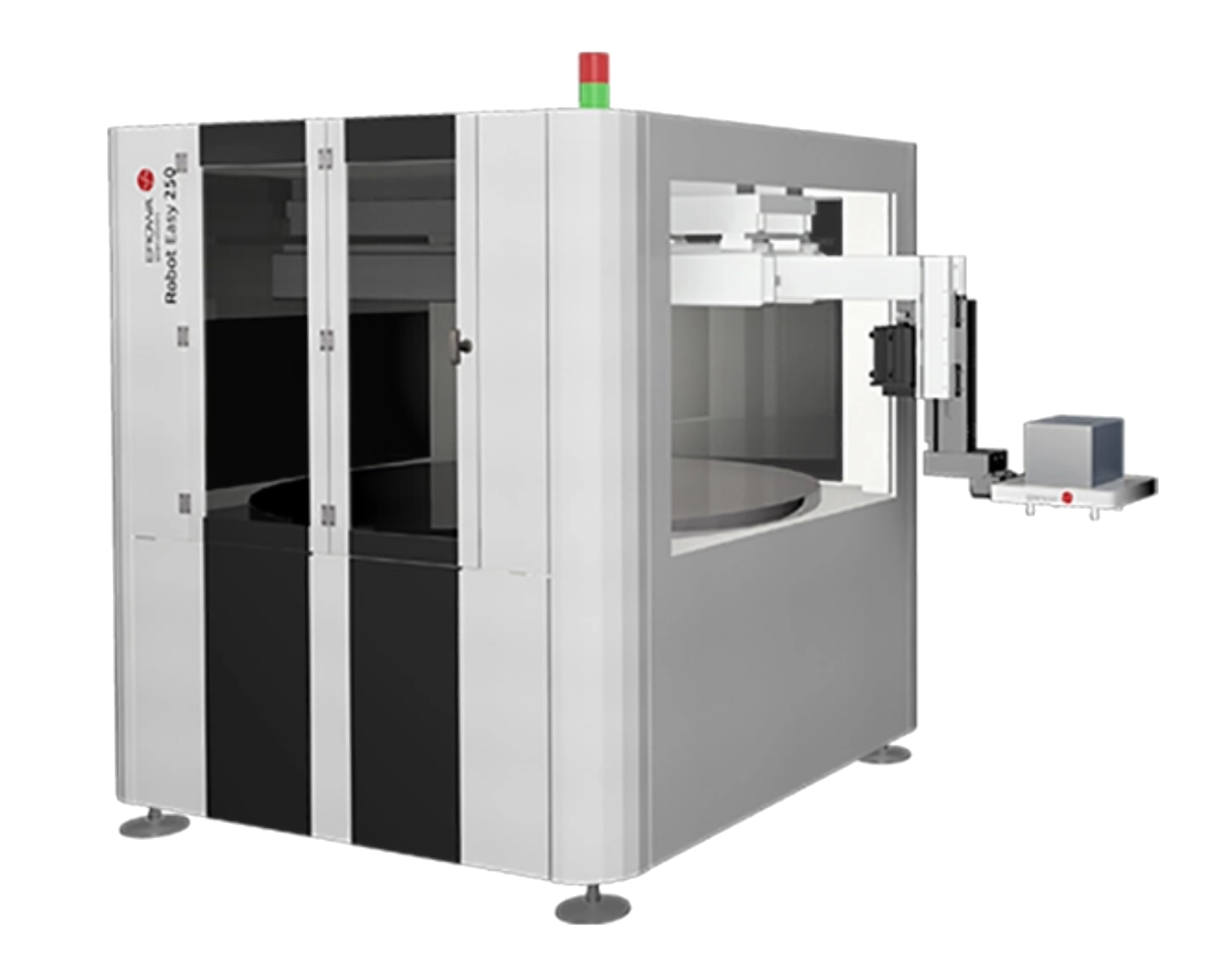

Superior setup

Walk-in or sliding door access. The set-up stations are integrated components of the LoadMaster production lines. Versions with lifting unit, with rotating and tilting table or with rotary table are available. All set-up positions are accessible with overhead crane.

Walk-in or sliding door access. The set-up stations are integrated components of the LoadMaster production lines. Versions with lifting unit, with rotating and tilting table or with rotary table are available. All set-up positions are accessible with overhead crane.

Superior augmentation

The facts

The facts

- From 500 – 4’000 kg transfer weight

- Up to 4 floors in the magazines

- Ergonomic set-up stations

- Clear process control system

Workholding

Systems

A standardized interface between machine and workpiece or clamping tool enable fast and precise setup.

Measuring

Systems

Eliminate set up times on machines, making them more productive and relieving them of operations that are not their responsibility.

Automation Solutions

Thanks to the Erowa flexible automation system, machine tools can significantly increase daily production hours.

Integration Software

The integration of machine tools and company systems (IOT) through a synoptic management software speeds up the dialogue between department.