LEONARDO

Very precise and extremely secure

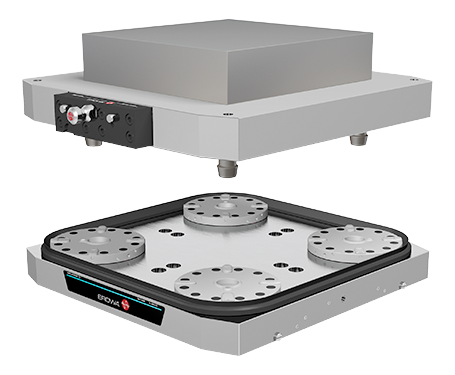

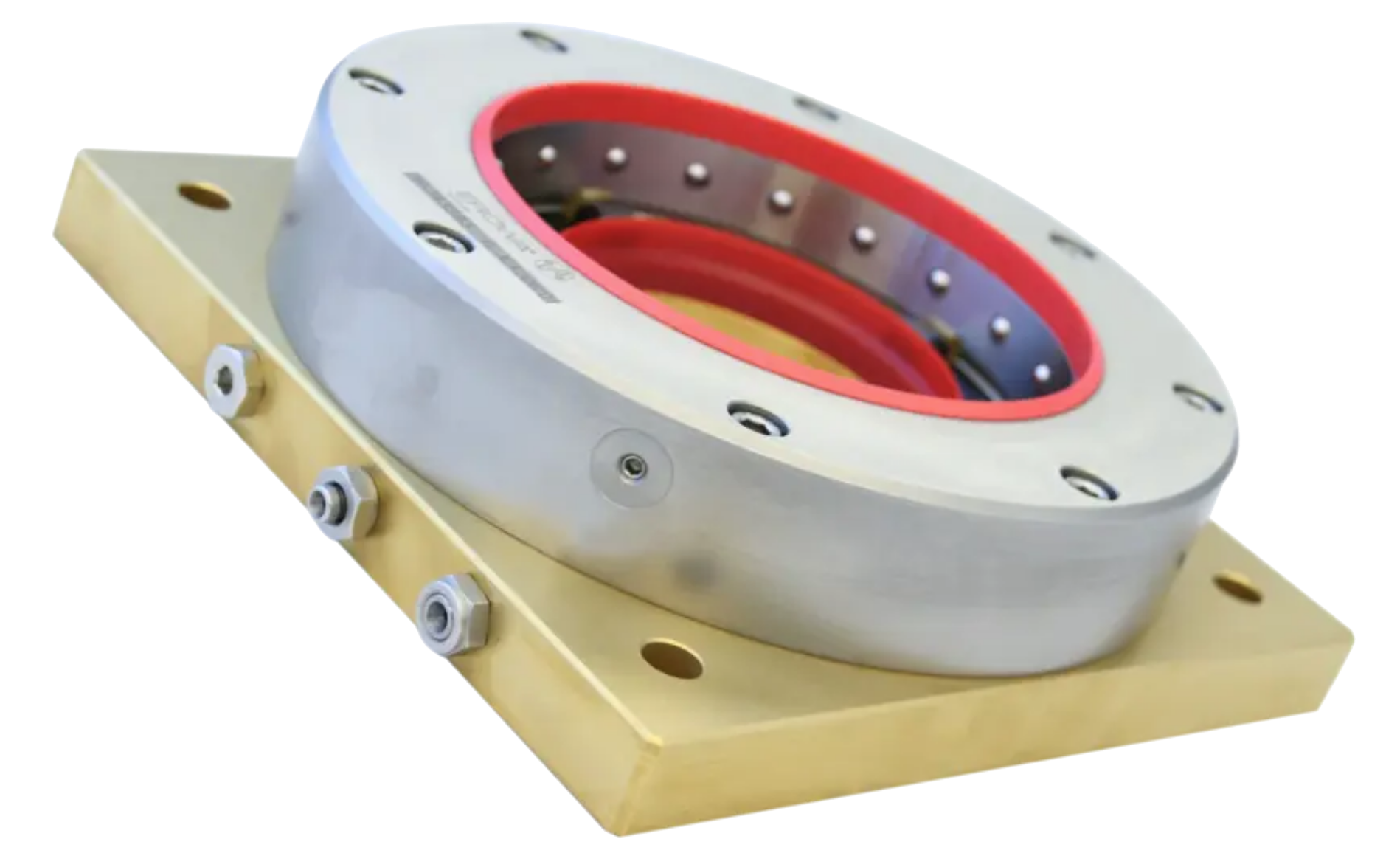

With a repeatability of 2 µm, the EROWA UPC (Universal Power Chuck) palletizing system leaves no wish unfulfilled in terms of precision.

Whether to palletize large workpieces on milling machines or to machine small workpieces on die-sinking EDM machines; the UPC palletizing system has the flexibility to handle most machining situations

Compact design

On a footprint of only 2×2 meters, the EROWA Leonardo loads milling machines with EROWA pallet sizes from ITS 148 mm to MTS 500 mm. If desired, mixed operation is possible with automatic gripper change. For example, there is space for up to 32 UPC pallets 320×320 mm.

On a footprint of only 2×2 meters, the EROWA Leonardo loads milling machines with EROWA pallet sizes from ITS 148 mm to MTS 500 mm. If desired, mixed operation is possible with automatic gripper change. For example, there is space for up to 32 UPC pallets 320×320 mm.

Long travel range

Leonardo is a pallet-handling unit with multi-level magazines. It has a transfer weight of 80 kg with an option of 120 kg available.. The X-axis has a long travel range giving it the ability to reach into large machines.

Leonardo is a pallet-handling unit with multi-level magazines. It has a transfer weight of 80 kg with an option of 120 kg available.. The X-axis has a long travel range giving it the ability to reach into large machines.

Loading station included

Pallets are moved into the robot via the integrated loading station. Leonardo automatically places the prepared pallets into an available magazine position.

Pallets are moved into the robot via the integrated loading station. Leonardo automatically places the prepared pallets into an available magazine position.

User-friendly loading station

The rotating plates on the loading station provide optimum access and space for setting up the palletized workpieces or fixtures.

The rotating plates on the loading station provide optimum access and space for setting up the palletized workpieces or fixtures.

Flexible magazine configuration

The various EROWA standard pallet sizes are optimally stored on the storage levels. Depending on the requirements, the levels are adjusted to each other in height.

The various EROWA standard pallet sizes are optimally stored on the storage levels. Depending on the requirements, the levels are adjusted to each other in height.

All important data at a glance

The EROWA process control system JMS 4.0 provides the basis for increasing effective machine time. Operators and planners can see in real time the status of the plant, the individual machines, the worklist and much more.

The EROWA process control system JMS 4.0 provides the basis for increasing effective machine time. Operators and planners can see in real time the status of the plant, the individual machines, the worklist and much more.

Workholding

Systems

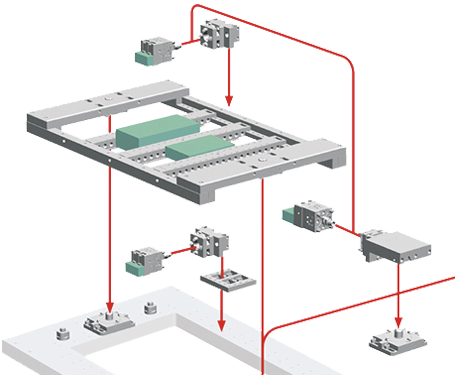

A standardized interface between machine and workpiece or clamping tool enable fast and precise setup.

Measuring

Systems

Eliminate set up times on machines, making them more productive and relieving them of operations that are not their responsibility.

Automation Solutions

Thanks to the Erowa flexible automation system, machine tools can significantly increase daily production hours.

Integration Software

The integration of machine tools and company systems (IOT) through a synoptic management software speeds up the dialogue between department.