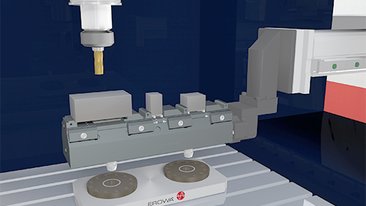

EROWA Clever Clamp System

Clever clamping

The EROWA CleverClamp System is the modular and universal workpiece clamping system that is tailored to the production of one-off parts and small series. It is simple to handle and versatile to use. Setting-up times are reduced, machine operating times increase and productivity is enhanced.

Modular and universal clamping

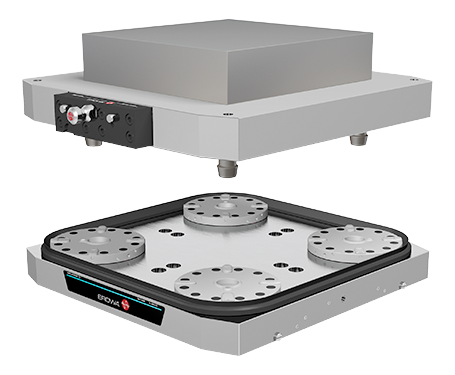

Thanks to the standardized EROWA UPC or MTS interface, the CleverClamp workpiece carriers can be positioned on the machine with speed and precision, and they can be used universally.

Thanks to the standardized EROWA UPC or MTS interface, the CleverClamp workpiece carriers can be positioned on the machine with speed and precision, and they can be used universally.

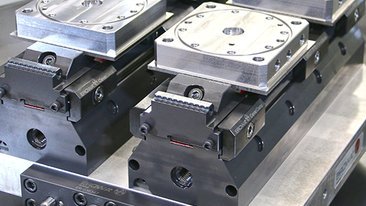

Faster set up times

Everything fits – the large and well-thought-out selection of various clamping and stop elements keeps the widest variety of workpiece shapes in any position you like with flexibility and precision.

Everything fits – the large and well-thought-out selection of various clamping and stop elements keeps the widest variety of workpiece shapes in any position you like with flexibility and precision.

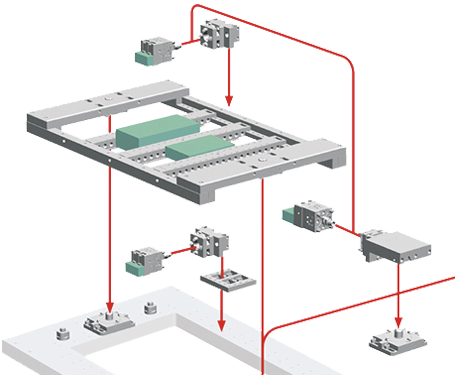

Reliable base

The base rails constitute the foundation of the CleverClamp workpiece clamping system. They can be used horizontally or vertically.

The base rails constitute the foundation of the CleverClamp workpiece clamping system. They can be used horizontally or vertically.

The matching clamping and stop elements can be positioned quickly with the help of the 2mm position toothing system.

Easy to handle

Setting up and resetting with only a few simple steps: position and attach the clamping and stop element, then clamp the workpiece.

Setting up and resetting with only a few simple steps: position and attach the clamping and stop element, then clamp the workpiece.

Various types of clamping surface

Depending on the material and workpiece, you can select the properties of the clamping surface.

Depending on the material and workpiece, you can select the properties of the clamping surface.

The clamping surface with stamp contours is ideally suited for the clamping of blanks at a minimum clamping height and of parts with angular errors.

Can be automated directly

The CleverClamp base rail can be automated directly. The robot places the workpiece carrier on the machine with precision and speed.

The CleverClamp base rail can be automated directly. The robot places the workpiece carrier on the machine with precision and speed.

The EWIS™ identification system provides you with a safe overviw of magazine positions and pallets.

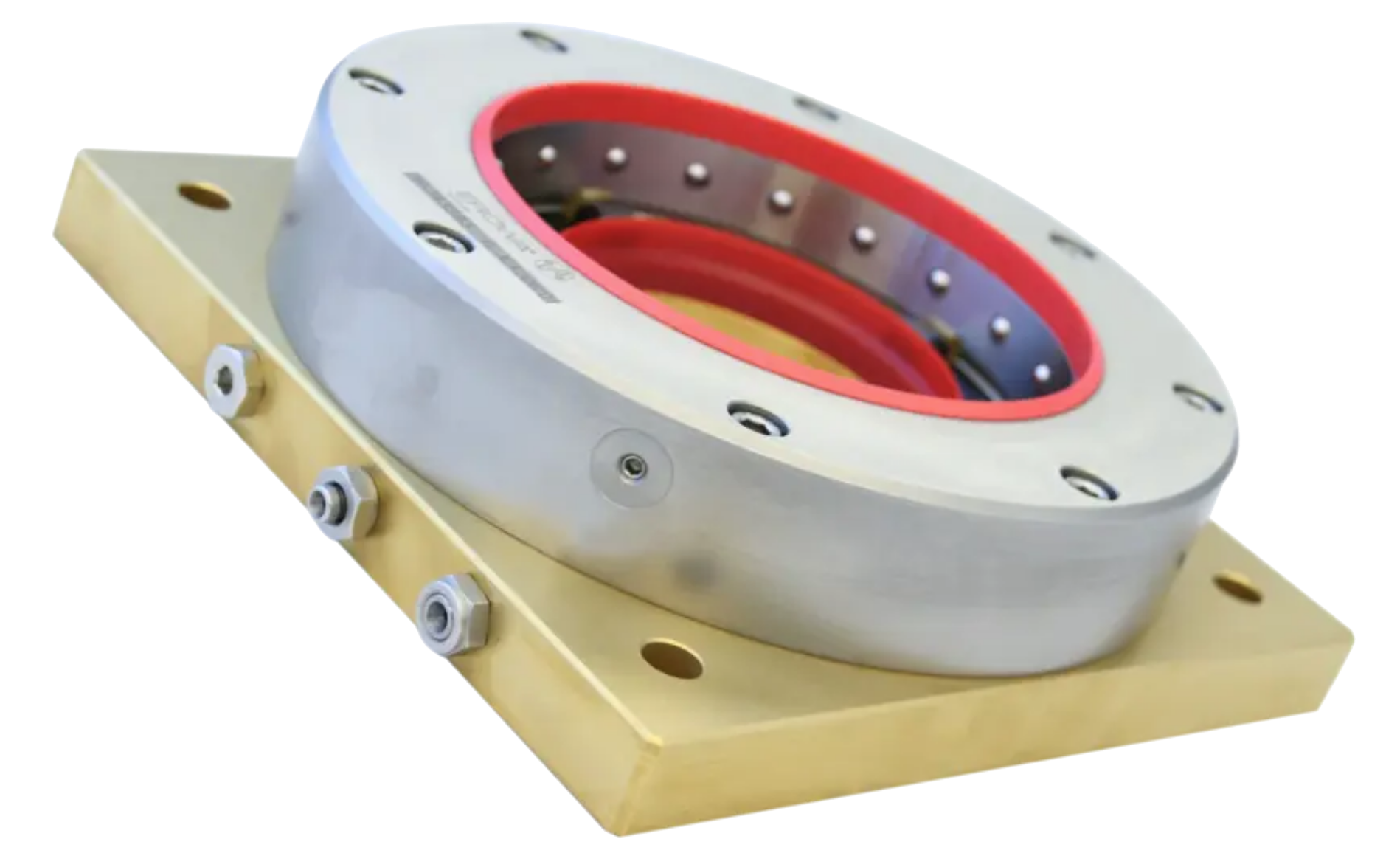

Workholding

Systems

A standardized interface between machine and workpiece or clamping tool enable fast and precise setup.

Measuring

Systems

Eliminate set up times on machines, making them more productive and relieving them of operations that are not their responsibility.

Automation Solutions

Thanks to the Erowa flexible automation system, machine tools can significantly increase daily production hours.

Integration Software

The integration of machine tools and company systems (IOT) through a synoptic management software speeds up the dialogue between department.